Handheld and split type ultrasonic cell disruptors have many similarities in function and application, but due to differences in design, usage methods, and application scenarios, they also have significant differences in certain aspects. The following is the main comparison between these two ultrasonic cell disruptors:

1. Structure and Design

Handheld ultrasonic cell disruptor:

Design: Handheld devices have a compact structure and are typically integrated, including an ultrasonic generator and an ultrasonic probe (usually replaceable). Users can directly operate the device handheld.

Volume: Compact in size, easy to carry and move, very suitable for small-scale experiments or on-site operations.

Operation mode: Users can operate by holding the probe, which is convenient to control and suitable for quick experiments or movement during operation.

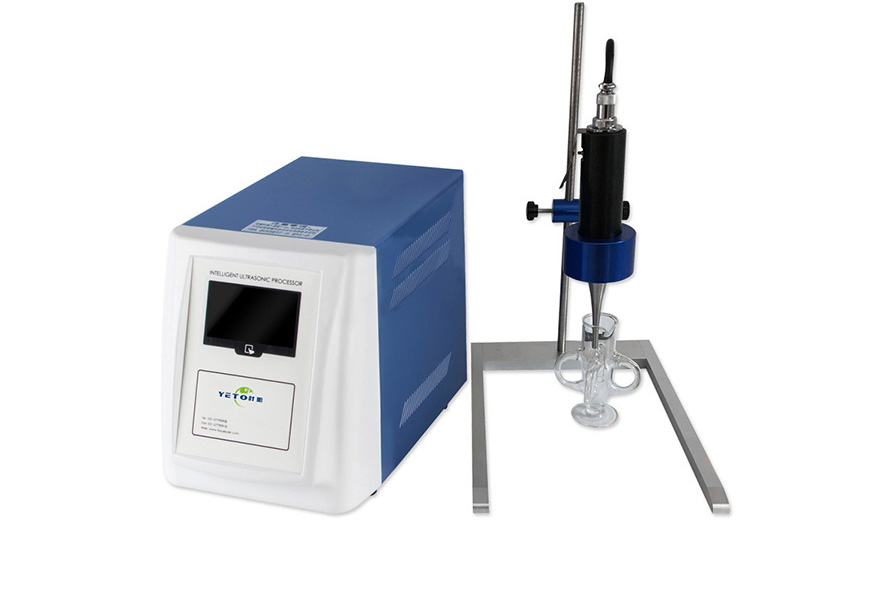

Split type ultrasonic cell disruptor:

Design: The split type equipment consists of an ultrasonic generator, a vibration control unit, and a probe (usually an independent probe with a transmission line). The generator and probe are separate and connected through cables.

Volume: Compared to handheld devices, split type devices have a larger volume and occupy more space. They are usually suitable for long-term fixed installation or batch operation in laboratories.

Operation method: During operation, the probe needs to be immersed in the sample and the parameters adjusted through the control panel, which is suitable for precise operation of the sample.

2. Application scenarios

Handheld ultrasonic cell disruptor:

Applicable scenarios: Due to its portability, it is suitable for small-scale experiments, clinical sites, field work, and other situations that require flexible use. Suitable for fast experiments, single processing, or work environments that require frequent movement.

Limitations: Compared to split type, it has a smaller processing capacity and is more suitable for rapid processing of single small samples.

Split type ultrasonic cell disruptor:

Applicable scenarios: Suitable for large-scale cell lysis experiments that require long-term stable operation, or laboratories with high requirements for cell lysis efficiency. Suitable for processing large samples or batch operations of multiple samples.

Limitations: Due to its large size, the operation is not as flexible as handheld devices, making it suitable for long-term use and not easy to move.

3. Processing ability

Handheld ultrasonic cell disruptor:

Sample processing capacity: Usually used for processing small samples, the amount of sample processed at once is limited (usually a few milliliters to tens of milliliters). Suitable for conducting rapid experiments on a small number of samples.

Power: The power is relatively small (usually between 50-500W), suitable for single processing of small samples, but may not be able to meet large-scale or processing requirements.

Split type ultrasonic cell disruptor:

Sample processing capacity: With a large processing capacity, it can handle samples of hundreds of milliliters or even larger volumes. Suitable for batch processing.

Power: High power (usually above 500W, even up to 1kW), able to work continuously for a long time, suitable for large-scale cell lysis or extraction.

The handheld ultrasonic cell disruptor is suitable for experiments that require minimal sample quantity, quick processing, and flexible operation, especially for small laboratories or clinical applications.

The split type ultrasonic cell disruptor is suitable for large-scale, high-efficiency, and precise experiments, especially for scientific research and industrial applications that require batch processing and long-term stable operation.

The choice of which type of ultrasonic cell disruptor to use mainly depends on factors such as experimental requirements, processing capacity, budget, and space.