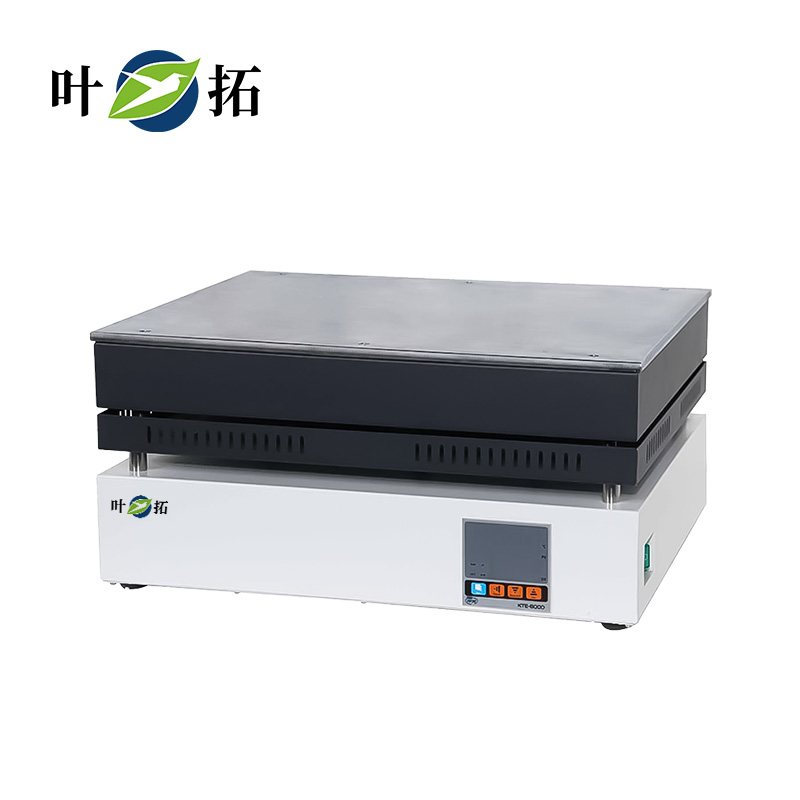

Product parameters:

Product model: DB-XAB

Power supply voltage: 220V 50HZ

Temperature resolution: 1 ℃

Temperature fluctuation: ± 1 ℃

Temperature control range: RT+0-400 ℃

Temperature control program: constant value mode

Temperature uniformity: ± 2.5%

Display mode: LCD screen

Working environment temperature: 5-40 ℃

Input power: 1500W

Heating plate size (depth x width x height mm): 3000x200

Dimensions (Depth x Width x Height mm): 200x300x220

Packaging dimensions (depth x width x height mm): 355x265x260

Tray load capacity: evenly weighed 30KG, maximum load capacity 50KG

Tray material: High quality cold-rolled steel

Timing range: 0-9999min

Overtemperature protection function: Forcefully turn off heating after instrument overtemperature alarm

Continuous working time at 300 ℃: 7 days

Net weight/gross weight (KG): 8/9

- Product Details

- Product manual

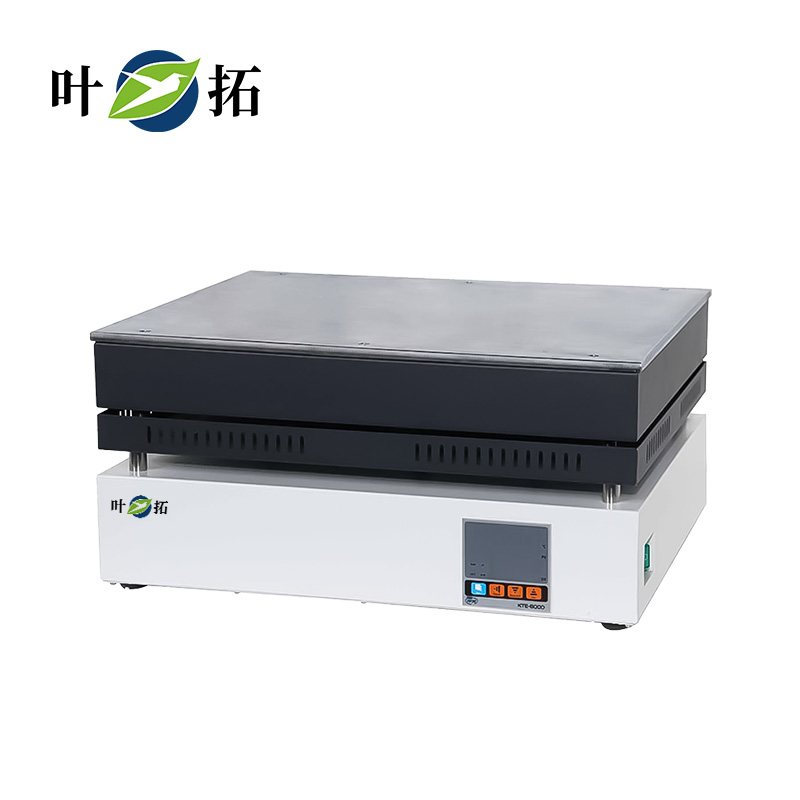

Ye Tuo DB-XAB Precision Stainless Steel Electric Heating Plate

Model: DB-XAB

Product Overview:

This product is suitable for baking, drying, and other temperature tests of chemical analysis, physical testing, heat treatment, and other items in laboratories of industrial and mining enterprises, health, environmental protection, biochemistry, scientific research and other units.

Characteristics of Ye Tuo DB-XAB Precision Stainless Steel Electric Heating Plate Products

The product shell is made of high-quality cold-rolled steel plate through stamping, and the surface is treated with spray coating technology. The surface of the plate is made of high-quality stainless steel S=8mm, which can prevent direct heating by open flame. It has the advantages of no open flame, fast heating, uniform temperature, safety and reliability, and high cost-effectiveness

Using LCD display instrument, beautiful and elegant, precise temperature control, PID parameter self check, automatic adjustment of heating rate, high temperature control accuracy

● Energy saving and efficient use of unique heating and insulation methods to improve thermal efficiency, energy conservation and environmental protection

The connecting components are made of anti-corrosion materials, and the chassis is treated with anti-corrosion spray coating, which can resist harsh corrosive environments

Alibaba Store

Alibaba Store Tmall Store

Tmall Store Jingdong Sstore

Jingdong Sstore