Product parameters:

Model: SX2-10-12NTP

Environmental temperature: 0-50 ° C

Temperature control range: room temperature -1200 ° C

Reachable temperature: ≤ 1100 ° C

Temperature control accuracy: ± 1 ℃

Temperature fluctuation: ± 1 ℃ (test point 600 ° C)

Temperature equilibrium: ± 3 ° (test point 600 ° C)

Heating rate: It takes about 10 minutes to heat up to 700 degrees Celsius

Furnace material: Ceramic fiber

Furnace size (mm): 400x250x160

External dimensions (mm): 720x580x730

Weight gross weight: ≈ 60kg

Volume: ≈ 16L

Input power: 6kw

Power supply voltage: 380V

- Product Details

- Product manual

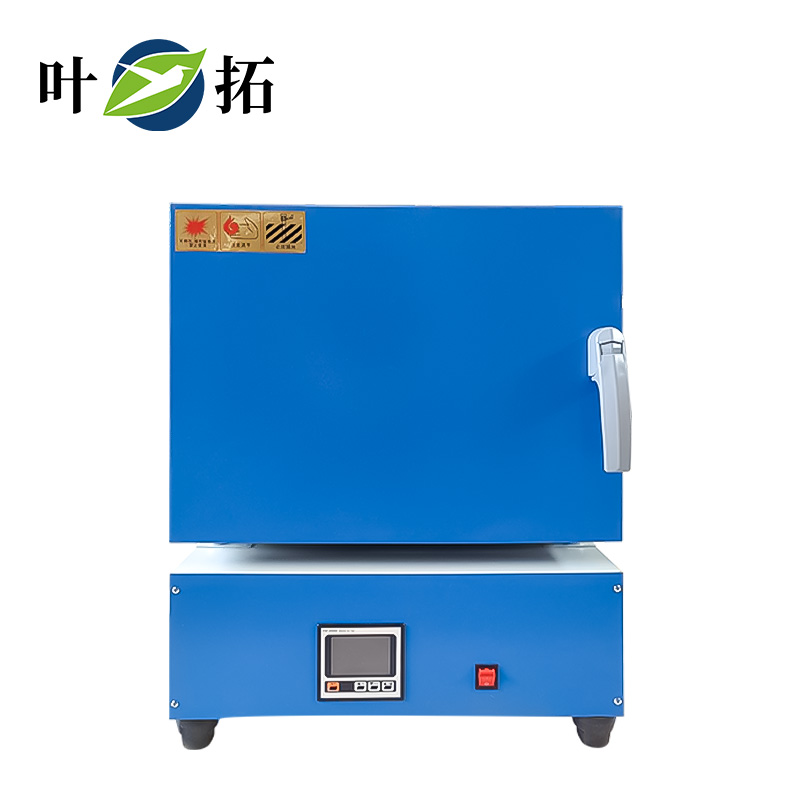

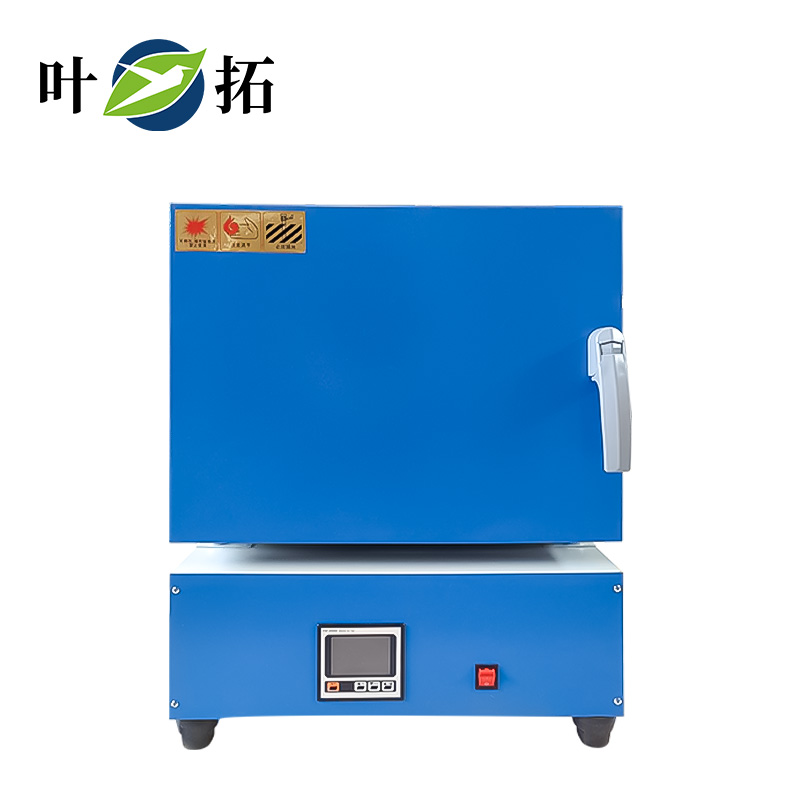

Ye Tuo SX2-10-12NTP Ceramic Fiber Box Resistance Furnace

Model: SX2-10-12NTP

Product Overview:

Ceramic fiber resistance furnace is a high-temperature electric heating equipment that uses ceramic fibers as heating elements. It has the advantages of high temperature stability, high energy efficiency, and high temperature control accuracy. Being able to rapidly heat up, it is an upgraded product of traditional furnaces, used for element analysis and determination in laboratories, industrial and mining enterprises, scientific research institutions, powder metallurgy, metal parts quenching, and other heat treatments that require rapid heating processes.

Characteristics of Ye Tuo SX2-10-12NTP Ceramic Fiber Box Resistance Furnace Products

Adopting a microcomputer PID controller, with high accuracy and no noise, overheating alarm.

The box body is made of cold-rolled steel plate, and the shell color is sprayed with plastic technology, which is baked at high temperature.

The inner side of the furnace door is equipped with refractory materials to reduce heat loss and improve the uniformity of temperature inside the furnace.

The heating elements are made of good materials, and the temperature inside the furnace rises quickly and evenly.

The box adopts double-layer protection inside, which can prevent heat dissipation while ensuring that the outer shell is not hot to the hands.

SX2 type box type resistance furnace, formerly known as "muffle furnace", is designed and produced according to the analysis method "GB212-77" standard requirements researched by the Ministry of Coal Science. In order to facilitate the maintenance of the furnace, the furnace core can be extracted from the furnace top, which is extremely convenient for maintenance compared to similar furnaces.

The electric furnace door is fixed on the electric furnace panel through a chain. The furnace door rotates flexibly. When closing, press the handle and fasten the door hook, so that the furnace door can be tightly attached to the furnace mouth; When opening, simply pull the handle lightly, unhook it, and place the furnace door on the left side.

Adopting an integrated structure, the oven can be started by directly connecting the power supply after purchase.

Alibaba Store

Alibaba Store Tmall Store

Tmall Store Jingdong Sstore

Jingdong Sstore