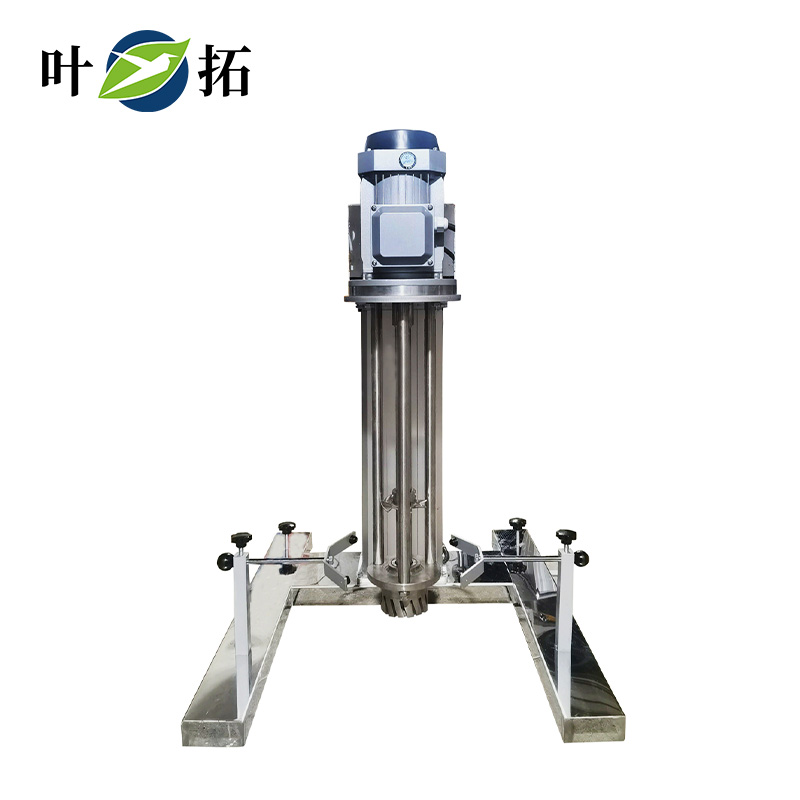

Product Parameters:

Product model: YTRH-2200D

Motor type: three-phase asynchronous

Voltage: 220V/380V

Speed (R/min): 0-3000

Lifting method: electric

Power: 2200W

Lifting stroke (mm): 500

Equipment size (mm): 750X620X1050

H-shaped base inner diameter (mm): 395X420

Spindle length/diameter (mm): 670/28mm

Emulsifying head ground distance: 50-80mm

Emulsifying head shape (optional): claw type/long hole/round hole

- Product Details

- Product manual

Yetuo YTRH-2200D Electric Lift Emulsifier

Model: YTRH-2200D

Product Overview:

The high shear emulsifier is a high-performance product newly developed by our company based on the development trend of advanced emulsification equipment. This device integrates dispersion/mixing/emulsification/homogenization functions. High efficiency, good mixing effect, and easy cleaning. Easy and convenient lifting and lowering. Widely used for dispersing/mixing/emulsifying/homogenizing materials in liquids in factories, research institutions, colleges, and medical units.

A high shear emulsifier is an efficient, fast, and uniform method of distributing one or more phases into another continuous phase, which is usually immiscible with each other. Due to the high tangential velocity generated by the high-speed rotation of the rotor and the strong kinetic energy brought by high-frequency mechanical effects, the incompatible solid, liquid, and gas phases are instantly uniformly and finely dispersed and emulsified under the joint action of corresponding mature processes and appropriate additives. After high-frequency cyclic reciprocating, stable products are finally obtained.

Product Features of Yetuo YTRH-2200D Electric Lift Emulsifier

● Choose three-phase asynchronous motor, no spark/dust, higher performance, low noise, sufficient power, can run for a long time, easily meet various high requirements for dispersion and mixing in semi production.

This product can choose 220V/380V power supply to meet different working environments.

Adopting a clamp to fix the material bucket design, the kettle body does not experience displacement when handling high viscosity materials.

The emulsification head adopts precision processing, which ensures smoother operation and better discharge effect.

Adopting a three-phase asynchronous motor, it can handle materials with high viscosity and can work continuously for a long time.

The base and distribution cabinet are both designed with stainless steel cladding to avoid cleaning and rusting caused by material contamination during use.

Claw type emulsifying head: The bidirectional suction method forms a bidirectional hyperbolic curve inside the container, and the large circulation vortex avoids dead corners caused by the difficulty of inhaling container materials, resulting in finer emulsification homogenization.

Long hole emulsifying head: suitable for rapid crushing of medium solid particles and mixing of medium viscosity liquids, the long holes provide a large area and good circulation for surface shearing.

Round hole emulsification head: it is suitable for mixing low viscosity liquid, with large shear rate, and suitable for the preparation of lotion and the pulverization and dissolution of small particles in liquid.

Alibaba Store

Alibaba Store Tmall Store

Tmall Store Jingdong Sstore

Jingdong Sstore