Product parameters:

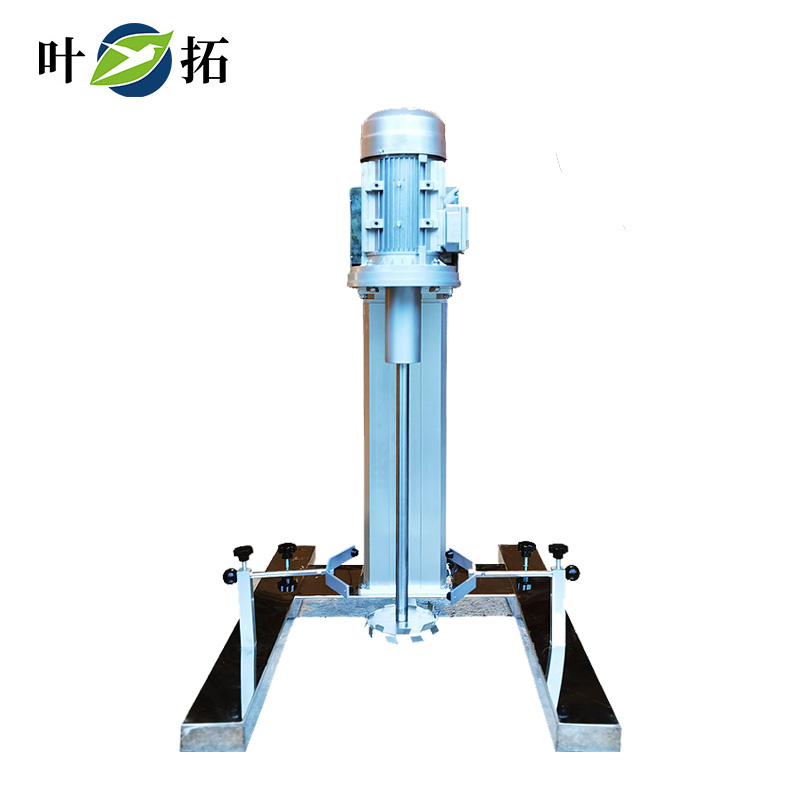

Model: YT-1100BPF

Motor type: three-phase asynchronous

Voltage: 220V/380V

Power: 1100W

Speed: 0-3000R/min

Lifting method: electric

Lifting stroke: 400mm

Equipment size: 750 * 620 * 950mm

H-shaped base inner diameter: 395 * 420mm

Spindle length/diameter: 430/28mm

Distance between spindle and bracket: 250mm

Distance from dispersion disk to ground: 80mm

- Product Details

- Product manual

Yetuo YT-1100BPF electric lifting disperser

Model: YT-1100BPF

Product Overview:

The pilot dispersion mixer integrates the functions of mixing and dispersing for multiple purposes, making it the most ideal semi production equipment for technicians. It has the advantages of sufficient power, low voice, no reversing interference, and no mechanical wear of carbon brushes. The number directly displays the shaft speed and is equipped with dispersing blades. It can adapt to the different work needs of technicians and directly calculate the relationship between the linear velocity of the mixing and dispersing blades, material viscosity, and chemical reaction rate based on the displayed shaft speed, providing correct data for large-scale production.

Application areas: The pilot dispersed throwing machine is widely used in factories, research institutions, universities, medical units and other institutions. It has been widely used in the development and experimentation of products such as pigments, inks, food, coatings, biology, physics and chemistry, and animal husbandry

Product features of Yetuo YT-1100BPF electric lifting disperser

● Choose three-phase asynchronous motor, no spark/dust, higher safety performance, low noise, sufficient power, can run for a long time, easily meet various high requirements for dispersion and mixing in semi production

This product can choose 220V/380V power supply to meet different working environments

Adopting a clamp to fix the material bucket design, the kettle body does not experience displacement when handling high viscosity materials

The dispersing disk is connected to the dispersing shaft using internal hexagonal screws, making it easy and flexible to disassemble and assemble, with multiple specifications to choose from

This machine uses a three-phase asynchronous motor, which can handle materials with high viscosity and can work continuously for an extended period of time

The base and distribution cabinet are both designed with high-quality stainless steel cladding to avoid cleaning and rusting caused by material contamination during use

Alibaba Store

Alibaba Store Tmall Store

Tmall Store Jingdong Sstore

Jingdong Sstore