Model YTS-650T

Output power 65-650W

10-100% adjustable note: can be set to step 1%

Working frequency 20-35KHz frequency automatic tracking

Processing capacity 0.1-500ml(Corresponding probe shall be selected)

Timing 0-9999M99.9s can be set

Ultrasonic pulse time adjustment 0.1-99.9s adjustable (ultrasonic on/off)

Temperature control 0-100 ° C, optional thermostatic device

Alarm fault, temperature, time

Input/display mode: 7-inch TFT touch control+direct-color medical resistance screen

Display content frequency, temperature, power and time

Automatic error correction, overload and overtemperature protection display of protection device program

Password is protected by user blank code

Optional luffing lever 2, 3, 6, 8, 10, 13

Optional high borosilicate thermostatic cup 50, 100, 250, 500 (ml)

Power supply AC 220V+5%/50Hz (110V60Hz can be customized)

- Product Details

- Product manual

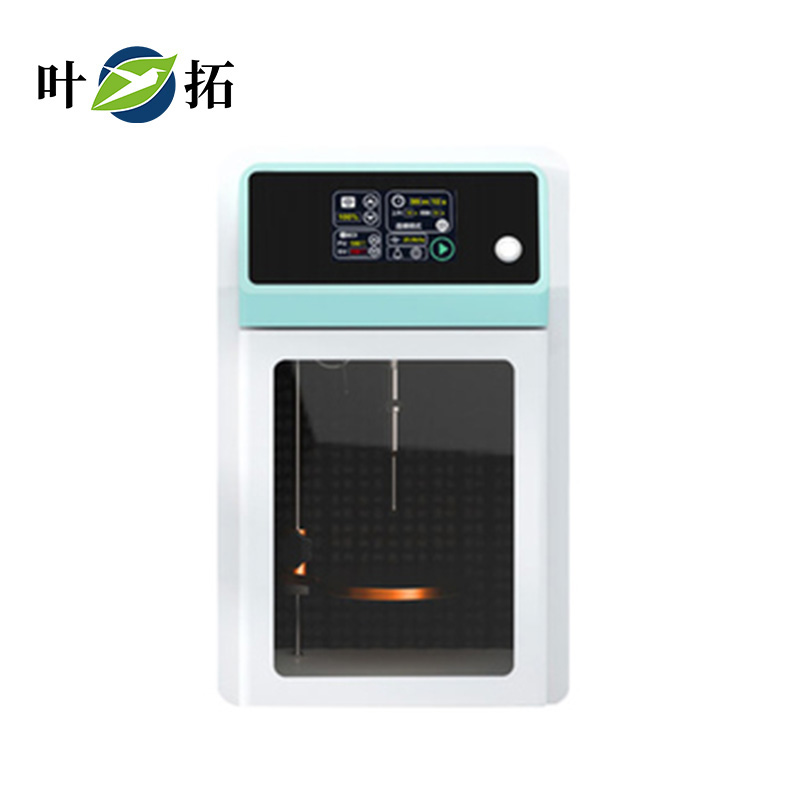

Yetuo YTS-650T integrated ultrasonic cell disruptor

Model: YT-650T

Product Overview:

Ultrasonic crushing is an application of sonochemical equipment that can be used for plant extraction, water treatment, solid-liquid dispersion, particle disintegration and aggregation in liquids, and enhancing solid-liquid reactions, dispersing larger particle aggregates into smaller particles. Stabilization refers to ensuring the long-term uniform dispersion of powder particles in liquid, including extraction of AO materials, cell, fine Jun, and viral tissue fragmentation. Extraction of intracellular contents. The dispersion, homogenization, and emulsification of material grains. Such as the dispersion of nanomaterials. Accelerate dissolution and chemical reactions. If used for chemical synthesis, this ultrasonic equipment is equipped with a soundproof box bracket, soundproof box, and low-temperature system.

Product features of Yetuo YTS-650T integrated ultrasonic cell disruptor

The overall device control screen and soundproof box are designed in an integrated manner, with a user-friendly human-machine interface and minimal laboratory space occupation.

The new generation of energy-saving digital ultrasound circuit automatically tracks frequency, resonant point, and power control, eliminating the need for frequent manual energy adjustment.

The equipment has an automatic recognition function for ultrasonic amplitude rods, and replacing titanium alloy amplitude rods of different sizes does not require manual adjustment. The instrument has an automatic recognition function.

Two ultrasound modes are available: continuous ultrasound mode and intermittent ultrasound mode.

The automatic amplitude and pulse compensation function maintains frequency stability, ensuring that the probe amplitude does not change due to changes in load during the ultrasound process.

The ultrasonic frequency converter adopts lead zirconate titanate crystal piezoelectric frequency converter, which is sealed to isolate water vapor and corrosive gases.

The ultrasonic probe is made of American standard TC4 high-strength titanium alloy material, which can work intermittently or run without load. The probe is not easy to wear and cavitation after long-term use (on-site verification is required, and the probe will not be damaged after continuous ultrasound for 30 minutes).

Alibaba Store

Alibaba Store Tmall Store

Tmall Store Jingdong Sstore

Jingdong Sstore