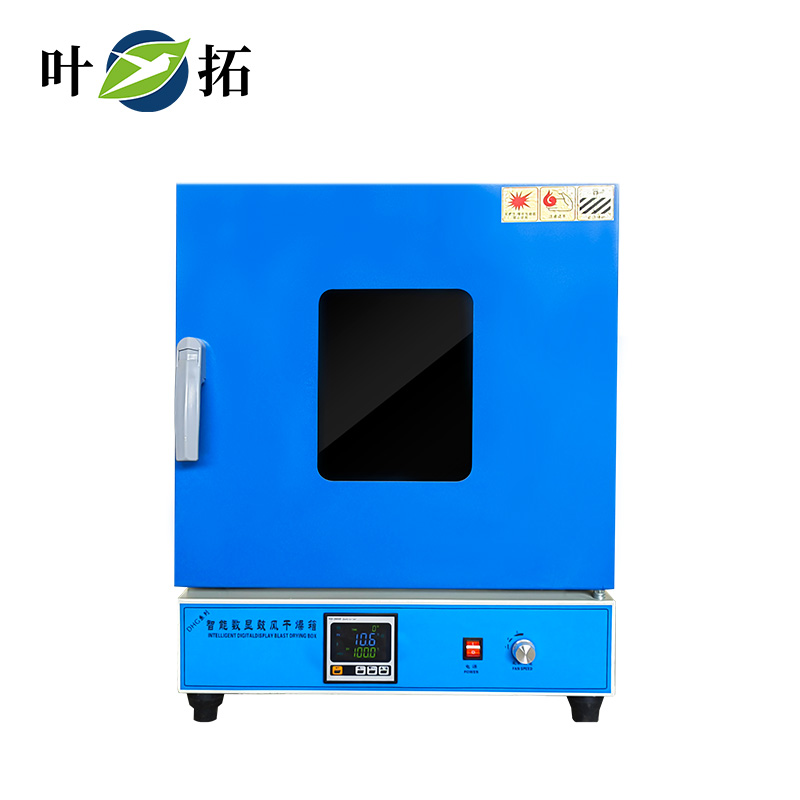

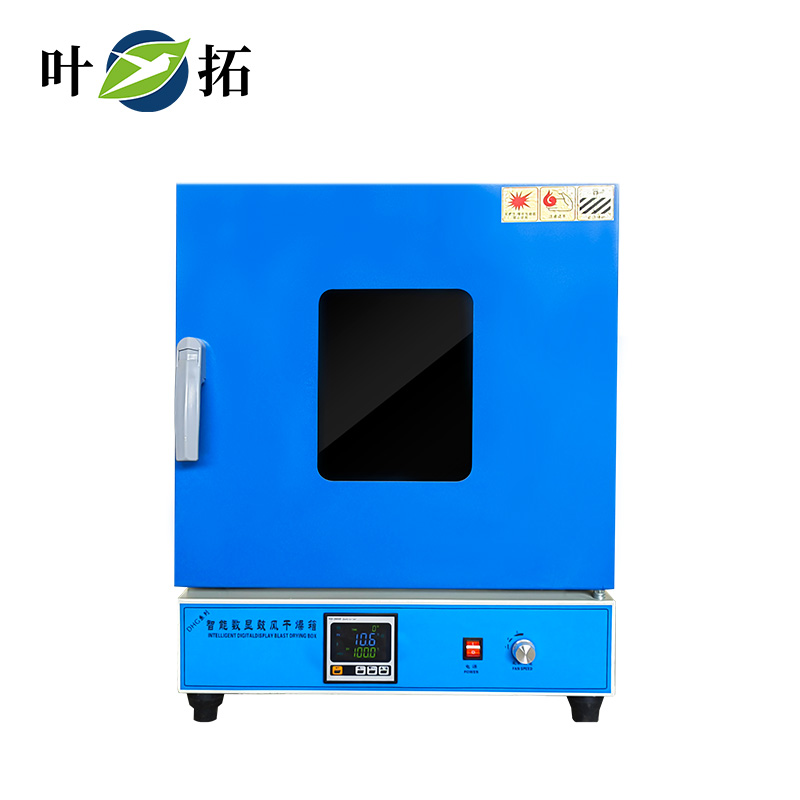

Product parameters Product model: DHG-9036A Temperature control range: RT+10~300 ° C Power supply voltage:~220V 50Hz Temperature resolution: 0.1 ℃ Temperature fluctuation: ± 1.0 ° C Temperature uniformity±3% (test point at 100 ℃ ) Load carrier standard configuration: 2 Timing range: 1-9999min Input power: 1600W Volume: 42L Working dimensions D x W x H: 35x35x35 (cm) External dimensions D x W x H: 51x47x64 (cm) Note: 201 stainless steel (vertical parameters above)

- Product Details

- Product manual

Ye Tuo DHG-9036A electric blast drying oven Model: DHG-9036A Applicable Overview: Products produced using advanced laser and CNC processing equipment are used for drying, baking, wax melting, and sterilization in industrial and mining enterprises, laboratories, research institutions, etc. Product characteristics of Ye Tuo DHG-9036A electric blast drying oven The box body is made of high-quality steel plates, and the studio is made of 201 stainless steel plates, which have a beautiful and novel appearance. The microcomputer intelligent temperature controller is equipped with dual digital display for setting and measuring temperature, timing, power suppression, and PID self-tuning functions, ensuring accurate and reliable temperature control. The hot air circulation system consists of fans that can operate continuously at high temperatures and suitable air ducts, with uniform temperature inside the studio. The over temperature alarm system immediately interrupts when the temperature exceeds the limit, and the sound and light alarm prompts the operator to ensure the safe operation of the experiment without accidents. Adopting a new type of rubber sealing strip, it can operate at high temperatures for a long time, has a long service life, and is easy to replace. It can be equipped with an embedded printer, which can print and record the temperature at different times, making it convenient to query the temperature control situation throughout the entire process, or an RS485 communication interface, making it easy to connect to a printer or computer. (Optional) Programmable LCD touch controller, capable of setting multiple program controls, displaying multiple parameters on one screen, convenient operation, and convenient program editing. (Optional) SMS monitoring and alarm system can be installed. When the user is not on site and the equipment malfunctions, the system promptly collects fault signals and sends them to the designated recipient's mobile phone via SMS to ensure timely troubleshooting, resume testing, and avoid accidental losses. (Optional)

Alibaba Store

Alibaba Store Tmall Store

Tmall Store Jingdong Sstore

Jingdong Sstore