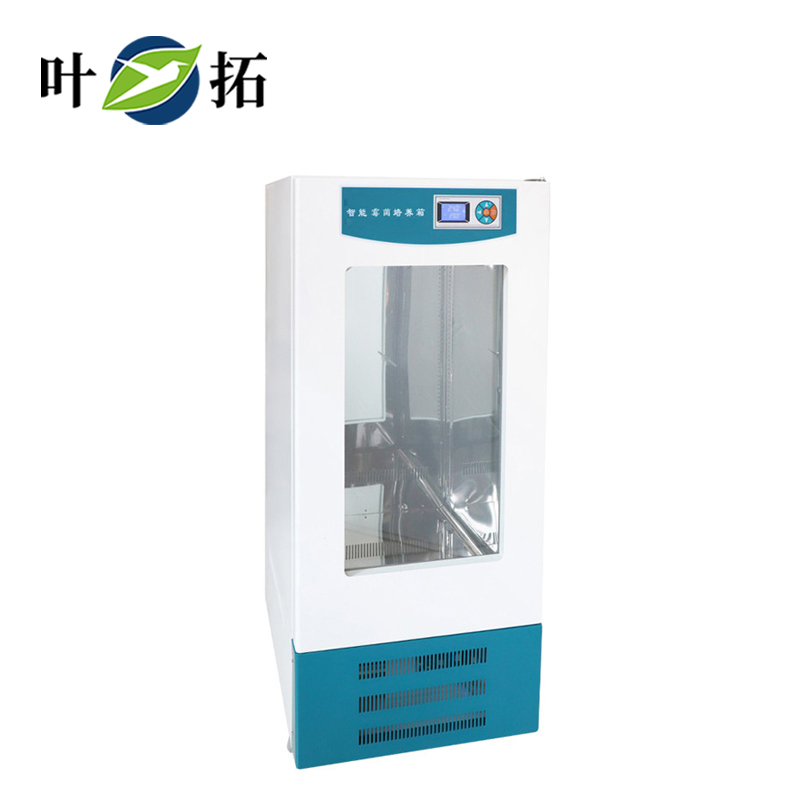

The Shanghai Yetuo mold incubator is a commonly used instrument and equipment in biological experiments. It has a cold and hot control function and can be set at a high-precision constant temperature. It is generally used for the cultivation of bacteria, molds, and microorganisms, plant cultivation, and BOD determination in water analysis experiments.

The working principle of the Shanghai Yetuo mold incubator is that the temperature sensor inside the incubator converts the actual temperature into an electrical signal, which is transmitted to the microcomputer. The microcomputer controls the operation of the refrigeration compressor or heater based on the pre-set temperature parameters to achieve the specified temperature inside the incubator.

We know that mold cultivation experiments have very strict requirements for environmental temperature. If the environment cannot reach the specified temperature due to instrument or operational issues, the experiment will fail. In this article, several precautions should be taken when using and maintaining a mold incubator, hoping to be helpful for your experiment:

1. Temperature and time settings are very important factors in mold cultivation experiments. You can set the desired environment through the "temperature setting" button and "time setting" button on the instrument. The instrument also has a timing function, which allows for the specification of the cultivation time.

2. Before using the mold incubator and after completing the experiment, it is necessary to clean the inside and outside of the incubator to keep it clean and dry.

3. The mold incubator should be placed in a dry, ventilated place away from direct sunlight, with a stable tabletop and no high heat or high magnetic field effects. Pay attention to leaving heat dissipation space around the instrument.

4. Do not frequently change the set value during instrument use to avoid overloading caused by frequent compressor start-up, which may affect the service life of the equipment.

5. During the experiment, the items inside the box should not be placed too tightly, and there should be air circulation space left. It should be ensured that the items do not block the air outlet inside the box and maintain normal air circulation inside the box.

6. Do not touch or collide with the temperature sensing probe inside the box to prevent damage to the probe and loss of temperature control.

7. The instrument is equipped with two sets of fuses. If there is a malfunction during operation, the power should be cut off first to check if the fuses are blown. If the fuses are intact, then check for other faults.

8. If the instrument experiences a malfunction where it cannot be powered on, check if the power plug is properly plugged in, if the power cord is broken, and if the fuse is functioning properly.

9. If there is a significant error between the temperature inside the box and the set temperature of the instrument, consider whether the temperature sensor is damaged, the fan is damaged, or the instrument is damaged. At this time, it is recommended to contact the manufacturer's maintenance personnel for inspection, and do not disassemble the equipment by yourself.

Alibaba Store

Alibaba Store Tmall Store

Tmall Store Jingdong Sstore

Jingdong Sstore